fireandwaterblog

July 24, 2013

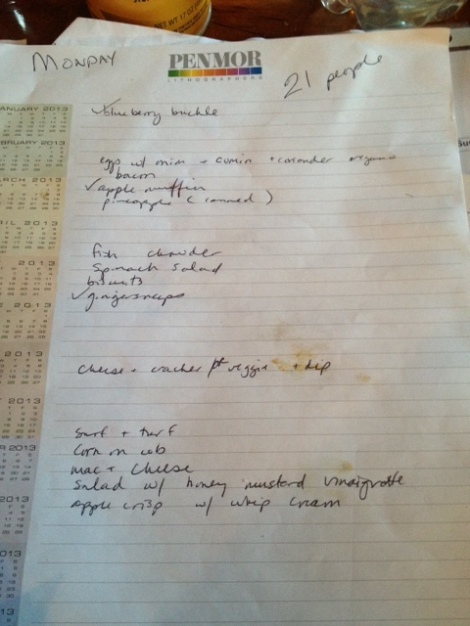

9 Knots and Indian Food Night

I didn’t post anything last week. I had one short day and a half off and somehow couldn’t find the time. I just finished 7 days on the Grace Bailey. It was an exciting week full of beautiful skies, a couple great!! days of sailing (reaching around 9 knots on Friday afternoon when we covered 30 miles in less than 4 hours!) and plenty of delicious food. It seems there’s lots to note from this week and I could probably write a blog post every day if I had reception on the water more regularly and enough time!

While sailing at around 9 knots in the Grace Bailey, this is what being heeled over looks like in the galley. Note the angle of the water coming out of that faucet.

Of note this week;

-

after my one rough day with the Mercantile stove during race week, I’ve been on a roll with the wood stoves on each boat. So much so that I am regularly getting an extra half hour of sleep and still serving everything on time and most importantly, getting the oven up to temperature in record time. This means I get up at 4:30 a.m. each day rather than 4:00 to serve the first snack and coffee at 6:30 a.m. This half hour of extra sleep is like heaven!!

-

also of note was a special surprise meal that I planned and executed Saturday night with my messmate for the week, Sally. I bought 3 cans of coconut milk and managed to have everything I needed to make coconut chicken curry, with cinnamon rice, sweet and spicy cole slaw, garlic naan (first time), raita, spicy apple raisin chutney, minty plum chutney, Indian pudding (first time I’ve ever tried a technique called a water bath where you bake something in pan of hot water) with whipped cream and an iced chai for dessert – we served this meal just after coming through a scary little squall on the way to Gilkey’s Harbor to 13 passengers and 6 crew members including ourselves. It was definitely like having a party in my mouth!

-

I didn’t set foot on land for 6 and a half days this week, perhaps the longest time I’ve been at sea yet.

-

Friday and Saturday afternoon we had great sailing reaching upwards of 9 knots at times (just after I finished baking the Indian pudding in the water bath!!) and covering 30 miles in less than 4 hours on Friday!! Both days were glorious with calm, slow moving mornings followed by high winds and lots of hot sunshine and cool air.

There is so much more to say about the rhythm of the days, the menus, being on the water, the crew, the Maine coast, tending fire and of course water, which I haven’t even written anything about yet, but I have only a short window of time before I have to be back for captain’s call – heading out for another 7 days on the Mercantile tomorrow morning – and plenty of errands to run and people to talk to before my bedtime at 9:30 or so.

July 8, 2013

FIRE: The Rhythm of the Day (Part 2)

Well, this week started out well. Easy Peasy as we say around here. After a great, though somewhat rainy 3 days out, we came back into Camden Harbor and boarded 12 new passengers. Thursday we headed out again for the Great Schooner Race, which started Friday morning in Gilkey’s Harbor.

Thursday I had my first tussle with the stove. From the very start of the day I could not get the temperature above 300 and it was often hovering around 250, definitely not hot enough to do most of what I need to do in any given day. I wrestled with it, pleaded with it, got angry, confused, etc. Nothing helped. Finally, without really understanding exactly why, at about 4:30pm, the oven jumped up to almost 500. Once it gets this hot, all kinds of things start happening since the whole hot water system is tied into the woodstove. Boiling water started coming out of the hot water faucet when we turned it on and the pressure in the hot water tank started creeping up. As soon as I realized this was happening, I turned on the faucets and drained our gravity feed “day tank” to release pressure and and get the water temperature normalized again. In spite of this challenging start to the trip, most all the food turned out pretty well. The pineapple curry chicken was dried out (that was in the oven when it shot up to the highest temperature) and some of the baked goods did more of a horizontal puffing than a vertical one. But besides that, the only thing ruined was my arms, which now look pretty terrible from all the new burns I got. Over the course of the day there were probably 10-15 new burns on my arms and hands.

Friday was the Great Schooner Race where all the different schooners start in one place and race through a course picked by the captains to a finish line. This year we started in Gilkey’s Harbor where you can see a big fancy house that used to be owned by Kirstie Alley and raced to Rockland Harbor with a few zig zags in between. We anchored in Gilkey’s Harbor with all the other schooners Thursday evening. Friday dawned beautiful — clear and warm with a slight breeze. It was so cool to wake up that morning and know that all the other cooks on the other boats were also starting their days as the sky turned from dark grey to pink to yellow to blue. The woodstove started right up that morning and got up to temperature much more quickly than usual. I didn’t burn myself all day and I did so much prep work that I was able to be on deck from about 9:00 to 11:00 and again in the afternoon for a couple hours while the race was still going on.

It was a gorgeous day with lots of wind with gusts up to 25 knots at times and plenty of hot summer sun. The Mercantile was in the coaster class and she came in 4th of 5 schooners. We received a “Spirit of ’53” award, which I couldn’t really figure out the meaning of. And there was a party in Rockland with free beer, live music and more food!

There’s so much more to say about the fire and about the rhythm of the day. But it is just now dark and time for me to go to bed so I can get up tomorrow and start it all over again. We ha.ve 19 new passengers and head out of Camden Harbor at 10am tomorrow morning. Thanks for reading this hastily written report!!

June 29, 2013

FIRE: The Rhythm of the Day (Part 1)

The stove top in the Mercantile Galley. The ladder is the main passageway in and out of the galley. The bars around the stove top keep things from sliding off when we’re heeled over.

I just finished a 5-day trip aboard the Schooner Mercantile. This is the first week I’ve started to really settle in to the rhythm of the days of sailing. Once the initial rush of provisioning the boats on Sunday/Monday is over and we’ve left Camden Harbor with our passengers, there is a sweeter, slower rhythm developing each day we’re at sea.

My days start at 4:00am. I wake up, get dressed and head straight to the galley to start the fire. At 4:00am on the eastern edge of the country as we hover around the summer solstice, the sky is just beginning to lighten. By 4:30 it is daylight and at 5:00am, the great golden sun starts to peek over the horizon. Usually, no one is up and around until almost 6:00am, though sometimes we have an early rising passenger who will sit quietly on deck or in the galley if it’s raining.

The fire box on the ShipMate cook stove, ash box is down and to the left, oven is behind the word “ShipMate”. The barely visible handle above the “S” is a door that can be open or closed and essentially creates a convection oven when closed, allowing the flame to wrap around the oven and provide more even heat.

The wood stove I cook on and with each day is a “ShipMate” made in Stamford, Connecticut. She’s a great curvy, sturdy cast iron lady bolted to the soles (floors) of the galley. The ShipMate company seems to be the place to get wood cook stoves for sea faring vessels. Their website states “Traditional solid fuel boat stoves and accessories hand built today the same way they were over 125 years ago and made to last another century. The Yacht and Ship wood stoves by which all others are measured.”

The firebox is quite small, maybe 10 inches wide and 6 inches tall at the mouth, though wider and taller inside and fairly deep. I lay the fire each morning with newspaper, a small bit of dryer lint, a strip or two of cardboard, some pieces of bark or scraps from the wood shop, a few smallish logs and an organic custom-processed Ecuadorian cacao bean for good measure (Nova Monda Cacao & Chocolate represent! http://www.novachocolate.com). I light the paper and within minutes the fire is steady and strong, except when it’s not, which is sometimes a possibility if it’s damp outside.

Mexican-style hot chocolate for a cold, blustery day. Made with Nova Monda jar chocolate, whole milk, cinnamon, cayenne pepper, vanilla and topped with freshly ground Ecuadorian cacao beans. Rich, creamy and SPICY!

I feed the fire with smaller pieces of wood for the first hour, about every 10-15 minutes or so, til there are embers and a raging flame. Within an hour, the stove top is at a cooking temperature and the water in the kettles is hot enough to brew the first pot of coffee. An hour and a half to two hours after the fire is started, the oven is hot enough to bake, about 350-400 in the hot spot next to the firebox on the top shelf and about 250-300 in the cold spot on the bottom shelf all the way to the right.

While I’m tending the fire for those first few hours, I have the galley (and the boat really) all to my self. I take that time to step out and watch the sunrise paint the sky, to adjust the menu as needed based on changing conditions and the ingredients that are most in need of being used, I also premix most of my baked goods for the day, keeping the wet and dry ingredients separate until right before they go into the oven.

There are generally at least 4 baked goods per day mixed and waiting on the counter by the time people are up and about; a pastry or muffin for the 6:30am snack (which is hopefully already baked by 6:00am), one for breakfast at 8:00am, one savory bread for lunch and one brownie or cookie or bar for the dessert after lunch. I usually have to start prepping breakfast before I finish the baking but by 9:00 or 10:00am all the baked goods are done except for dinner’s dessert, which I do after the 3:00pm snack.

When I took the job here, I was unsure how the wood stove cooking would go — would it be really hard? Would I burn things? Would I accidentally let the fire go out? How would I manage the 100 degree temperature difference from one side of the wood stove to the other? How would I know when things were done? I was full of questions, but also a great curiosity. As it turned out, it seems these wood burning cook stoves and I were made for each other. Once I learned that most things had to be covered in foil, it’s been easy, or maybe more accurately, it’s been very intuitive for me to learn how to work with the stove and wherever she’s at in any given moment.

The best lesson I’ve learned in working with this stove is to be in the moment. If I was set on getting a particular temperature at a particular time or if I was intent on control, I probably wouldn’t survive this job. Instead, I’ve had to learn to work around the 100-200 degree difference between the two sides of the oven, how to know when foil is necessary or not, how to adjust everything when all I have to burn is oak as opposed to pine, how to adjust everything when it’s been raining for days and the fire’s food is impregnated with moisture, how to use the wide open expanse of the stove top to get anything from high boiling heat to a heat low enough to melt chocolate, how to just let go when the fire refuses to cooperate for no logical reason, how to bake anything and feed the fire safely while we’re heeled over sometimes almost to 45 degrees (or so it seems), how to release the smoke when it starts filling the galley either by opening the ash box door, adjusting the fire box door or opening the convection damper (or all 3), and how to laugh it off and salvage whatever’s salvageable when I do accidentally burn something. There are so many variables and so much surrender required to cook well on a sailing vessel over a fire.

Next week, part 2 . . .

June 24, 2013

A Few Days of Sailing and A Song!!

Grace Bailey and most of her crew; from left to right, Mike, Johnny-tar, Jerika, Gus, John. Missing is Captain Ray and of course myself. Gus and John were along for the ride this week and not a normal part of this boat’s crew.

This past week of sailing was the first week where the weather’s been nice every day. Also my first week on the Grace Bailey, the largest and oldest ship in the Maine Windjammer Cruises fleet. She was built in 1882 as a cargo vessel hauling granite and lime and lumber and other things to and from the Maine coast. She even once sailed all the way to the East Indies.

The first 3 days of this week, I was training a new cook, Becca. Much like me, she didn’t want a whole lot of instruction beyond tips and techniques, so I mostly just had an easy 3 days of sailing, hanging out, trying to stay out of the way and generally relaxing aboard the Bailey. During my time aboard as a passenger I learned to splice rope and tie a bowline knot. Both of these seem like they will come in really handy for the rest of my life. A well-spliced line will create a loop in any size rope that seems to have grown there — strong, solid, able to withstand heavy amounts of pressure but also able to be undone if needed. A bowline knot (according to my sailor co-workers) is useful for similar reasons — it won’t ever come undone by accident but is easily undone by hand if needed.

The second part of the week, I did my first cooking on the Grace Bailey. Her galley has many nice features, including a larger and more well-designed icebox, an ice water tap and a lot more storage. The woodstove is more difficult to keep going and a little more unpredictable than the Mercantile’s. The Mercantile galley’s amenities include more counter space and a 2-basin sink with a dish drainer as well as easy access to almost anything I need at any time. The Mercantile seems to be designed for the cook and the Grace Bailey galley for the comfort of passengers. Sort of . . . the reality is that each galley has perks and each has downfalls, as with all things.

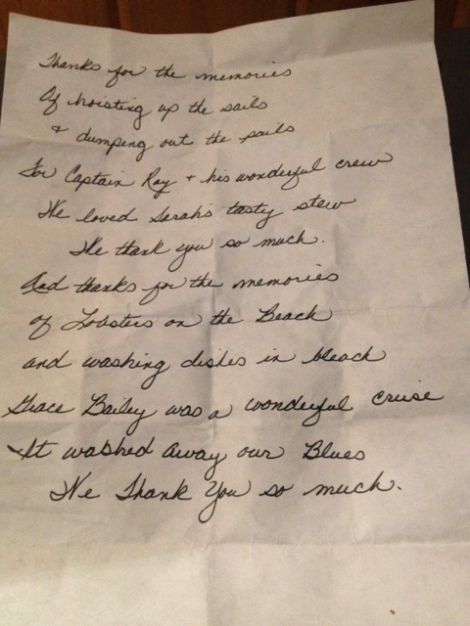

The highlight of my week was the last night when our awesome passengers composed!! and performed a song for us on deck after lasagna dinner. The meal was a veggie and a pork lasagna, green salad with balsamic vinaigrette, bruschetta and an apple blueberry crisp with whipped cream. The lyrics to the song are here:

Regardless, I will be setting sail again tomorrow morning on the Mercantile and I’m looking forward to going back to the boat where I cut my teeth on this wild adventure of sailing, cooking and tending the fire, the feast and the belly at sea.

About to lose power and no place to plug in. See you next time!!1

June 16, 2013

Some Photographs, Finally

I just came in from my first 6-day trip on the Schooner Mercantile. It was a long week and I’m feeling pretty tired on this beautiful Sunday afternoon. I’m including here a bunch of photos from my first few trips.

A glorious surprise day off a week or so ago found several of us hanging out on Curtis Island drinking gin and tonics, philosophizing on life and enjoying the view . . .

The Mercantile and her Captain, Andy, as he took me ashore to set up the lobster bake. To the left, there was a bald eagle perched in the tree.

Lunch aboard the Schooner Mercantile: Vegetable Beef Soup, Green Salad, Irish Soda Bread and Peanut Butter Cookies

June 9, 2013

Fish Out of Water (Part 2) — My FIRST EVER!!! Video included

Well folks, the Mercantile crew is getting ready to go back out on the water. Tonight we load 12 passengers and we sail from Camden Harbor around 10am tomorrow morning. Mid week, 2 passengers will disembark and we’ll add 16 new passengers (or thereabouts). I’m excited to be going back out and to re-kindle the fire in the morning.

But, for now, I am posting this video — really my first ever attempt at video — of the Grace Bailey’s trip to the ship yard a few weeks ago. It’s not that exciting, but it’s a little taste of what it’s like to be on the deck of the boat. We are not under sail in the video, but instead are being pushed by the yawl boat from Camden to Rockland.

Check it out here: https://www.youtube.com/watch?v=vZRkV1Qno_M

After getting the Bailey up on blocks and hauled out of the water, the Captain made an assessment of the hull, which was then scraped by hand and repainted over the course of our 3 days in the yard. The scraping was dirty work, mostly done by Jerika, Becky and Jonathan. I spent most of the time in the ship yard touching up paint on the deck and painting the water line (enjoying the privileges of being the ship’s cook) — cutting in with a hand held paint brush the transition from green to red that is visible just above the water line when the boat is in the water.

Prior to going to the yard, Jerika, Becky and I spent a rainy afternoon “spinning oakum”. Oakum is a pine-pitch-soaked hemp fiber that is used, along with cotton, to fill the gaps between the hull boards while the boat is out of the water. It comes in tightly rolled bales that have to be cleaned and then lightly pulled so that the fibers are a consistent width, thickness and in the longest strands possible. These strands get looped like thick skeins of yarn to present to Geno, who seems to be the go-to guy in New England for doing this traditional style seam repair on wooden boats, once the boat is out of the water.

He arrived on the last day we were at the yard. The questionable seams were reamed out with a chisel and then cotton was packed into them using a hammer and chisel. On top of the cotton, the oakum was then pounded into the seams. Once that was finished, I think the seam was brushed over with a sort of sealer and then finally painted. Since I just learned how to spin raw wool using a drop spindle, it was really interesting to work with a new fiber. The personality of each fiber is so different and besides that, the intended use for each fiber also creates a whole different experience of working the raw material.

I keep getting kicked off the internet at the library so sorry for the abrupt end. I will be back in a week. Thanks for reading!!!

June 3, 2013

A Fish Out of Water (Part 1)

A view from the helm of the boat showing the entrance to the ship yard and the tracks we rode up and out of the water

This past week, most of the Maine Windjammer Cruises crew were back in port. We arrived back to Camden on Sunday, May 26 after another rainy weekend trip. The sun came out on Monday, which was also Memorial Day, and it seemed like the whole town of Camden had changed over the weekend. The harbor was starting to fill with boats, the Public Landing (which is like the front yard for those of us living on the boats) was filled with people, the small schooners (the Olad and the Surprise) that run short trips out of the Harbor every few hours were moving passengers through at a brisk rate. There was even a Memorial Day band playing on the Landing at 9:00am in memory of all the fallen sailors and a short parade through downtown. Despite the previous week of cold and rain, Memorial Day seemed like the true beginning of the summer season.

Since I arrived a month ago I’ve been hearing that at some point we would take the Grace Bailey to the ship yard. She is the oldest ship in the fleet and is considered the flagship of the company. She’s been restored using more traditional methods than the other two boats including pitching on the deck and “hackmatack knees”. There’s a great write up of her history on the Maine Windjammer Cruises website so I won’t go into too much detail here. Needless to say, she is an impressive vessel, the largest in the fleet, whose aft cabin is still original and even contains a small piano!!

Every time I heard the ship yard mentioned, all I could think about was the opening fight scene of one of the recent Sherlock Holmes movies — the one with the giant — where they end up fighting in a ship yard and accidentally cutting this huge boat loose, creating a cascading effect of violence upon violence. Like so much having to do with boats, there always seems to be an element of danger hovering around the scene and going to the ship yard with the Sherlock Holmes movie in my mind wasn’t any different.

At high tide on Wednesday, five of us set out from Camden for the two hour ride to Rockland. We had to carefully slide the Grace Bailey out from between the Mercantile and the dock, which was a tricky undertaking in and of itself. But once she was loose, we headed out of the harbor with Captain Ray at the helm, turned on the reggae and enjoyed the sun while the yawl boat pushed us to Rockland. We pulled in to the ship yard and Captain Ray told us what to expect. Mostly, we just had to listen to the guys on the “cradle” or car that was going to hold this 60 ton vessel in place as she was pulled up and out of the water on these sort of railroad-track looking things. There were 2 guys on either side of the cradle, which had about a third of its height (about 10 feet) sticking out of the water when we pulled up and a diver under the boat checking the alignment on the blocks while she was still in the water. One person was on shore operating the winch that pulled the boat out of the water.

Basically, you have to sort of shimmy the boat into the proper position using lines (ropes) that connect the boat to the cradle at various angles. The boat ends up resting on sets of blocking (2 or 3 on either side and a line of blocking running the length of the bottom of the boat) that are attached to

the cradle. The diver directed those of us on deck and on the cradle to pull our lines in the right directions and with the right tension so that eventually the Bailey was in position and we started getting pulled slowly out of the water.

While still in the water, the boat is fluid, able to be moved in slight (or large) increments by the turning of the wheel/rudder or the easing or hauling on various lines or the movement of the diesel powered yawl boat. She is highly responsive to the movements, actions and decisions of the captain and his crew. Once out of the water, the boat is a brittle mass of wood — still impressive, still beautiful, but no longer responsive. She is truly like a fish out of water, unable to function outside her native landscape of current, waves and wind.

Stay tuned for Part 2

May 27, 2013

Sea Legs

First off, thanks a lot for reading everyone and for commenting and following this blog. It means a lot to me to know people are checking it out so keep it up AND please feel free to share around to friends

Just got back into Camden Harbor after three back to back trips for a total of about 8 days at sea. The Mercantile and her crew (myself included) will be in port for another week or two before heading back out. I am grateful for the break and looking forward to regrouping. Most of this past week it rained. This makes the galley quite cozy since it’s the only place with heat on the boat and tends to drive all the passengers into the warmth generated by the heat I use to prepare their breakfast, lunch and dinner. The galley is small and tight, with not much room to move around and there are at least 3 active leaks through the overheads (which in other contexts are called ceilings). Since my days in the galley run from (approximately) 4:00am to 7:00pm with a few breaks, this made for a very long week of constant company.

Friday night, May 24, there was a lunar eclipse, the third in a series of eclipses that spanned the last full moon cycle. It was also a Super Moon, where the moon is at its closest transit to the earth. That night, the seas were big. We were anchored in Pulpit’s Harbor. We had lobster and steak on the deck with a potato salad, caesar salad, corn on the cob and a zucchini chocolate cake with a to-die-for, made on the fly chocolate sour cream frosting. As we all settled in for the night, the weather was getting stormier and the seas more active. When I lay down in my bunk, the whole boat was rocking and rolling side to side as she rode the large, deep swells coming at us from the open ocean. It was the most movement I’ve felt at any time while we’re at anchor and I drifted off to sleep considering the ancient important connection between the moon and the ocean waters, each inextricably linked with the other no matter what we human beings are busy doing on land.

This whole past week has been rain and cold and fog and rough seas. On Saturday, May 25, the day after getting rocked to sleep, we set sail around breakfast. The winds and the seas were high and it was raining steadily with gray skies and some fog. I was feeling pretty ahead on my lunch prep so I took a chance to sit down. The seas and winds roughened quickly and soon I got up. Lunch took about twice as long as normal since the boat was more or less leaning over at a 45 degree angle in one direction or another for the last 2 hours before lunch. It was the first time I had experienced pots sliding around the stove or having to tie our coffee dispensers to the overhead in order to keep them on the counter. I also had to essentially hook my foot or knee or other body part around the edge of the counter while doing anything in the kitchen. At one point I was chopping onions on the counter and left the knife pointed out into the dining area and realized I could easily impale someone with a knife if we hit a particularly rough patch. So, another lesson learned about cooking on a boat, luckily not the hard way.

Since I started living on the boats at the beginning of May, I have experienced sea legs when I come back on land. The feeling of your body slightly moving back and forth trying to adjust to the shifting waters that are no longer underneath you. Since we started sailing (and especially after this past weekend), the sea legs have gotten more active. When I’m on land now, I have the experience of almost constant movement and can feel my muscles shifting, searching for a balance they are finally learning to find on the open ocean. Besides the constant swaying I feel now on land, I also find myself not trusting whether the land will be where it seems like it is in front of me as I walk, one foot in front of the other. The constant movement and tilting of the boat, makes every part of each step you take, from your toe touching the deck to your knee engaging to the actual movement from one place to another, an adventure. It is certainly making walking on land an adventure also!

Thanks for reading and see you here soon!!!!

May 20, 2013

Setting Sail

Well, I was going to write a post about “fit out”, which is getting the boats (there are 3) ready to sail and living on the boats in Camden Harbor for 3 weeks, but now that I’ve returned from my first weekend sailing — and cooking — that seems like old, boring news. Mostly it involved lots of sanding, varnishing, painting, cleaning and learning how not to hit my head so often on all the funny little corners and tight spaces.

My first sail started Friday afternoon, May 17. There were 23 passengers including Captain Ray Williamson (the owner and captain of these boats) and his wife Ann (who was the first cook on the boats). With the crew and including myself, there were 29 mouths to feed starting with Friday Dinner. It was VERY windy as the Mercantile left the harbor at about 3:30pm. Once she was out of the channel and on open water, we raised the sails and I finally understood what it means to be on a sailboat.

The immense power of the wind in those sails is a little terrifying at first. Once the sails were raised, they filled with wind and began pulling that giant old vessel across the open water at quite a clip — later, Captain Andy, the Mercantile’s new captain who’s been with the company for 8 years, said we were going at about 8 or 9 knots or so as we started out, which I gather is pretty fast.

There is so much to say about just the experience of raising the sails (which is wicked hard) or the experience of feeling the boat rolling and rocking around on the water (which made me wicked nauseous) or the actual experience of feeling the sails catch the wind and watching Captain Andy steer the boat from the aft deck at a big metal wheel like you see in the movies (which was wicked cool, especially as you realize what a dance it is between wood, wind, water and human ingenuity), but I mostly want to write about my first experience cooking on a wood stove.

I started the fire around 11am the morning we left. I mixed up a chocolate zucchini cake and put it in the oven around the time we started boarding passengers at 2:30pm. I’d been told so many things by so many people about cooking with wood but now here I was, face to face with the flames — made from dried out trees and ignited with paper and a small spark — and the metal of the old cook stove with her few moving parts and a big, yawning mouth. The first time I checked the cake, I realized I had forgotten to put the foil over the top to keep it from burning. From there on out, it was smooth sailing with the stove and some intermittent nausea from the not-so-smooth sailing of that blustery first trip.

First night’s dinner was a captain’s cook out on deck — Maine lobster and corn boiled and steaks on the grill, cooked by the Captain(s). I provided caesar salad, pasta salad and that chocolate cake for dessert. After setting anchor, and as the sun set, the seas calmed so that it almost seemed we were sitting in the middle of a large lake. I sat on deck with the crew and a few passengers and took in the familiar view of the islands of coastal Maine all around us and the stars rising on the horizon and slowly becoming visible overhead and reflected in that calm water.

The next morning I was up at 3:30am to start the wood stove so I could have it hot enough to make coffee, hot water and a snack to go up on deck at 6:30am and then full breakfast at 8:00am, then lunch at noon, another snack at 3:00pm and dinner sometime between 6 and 7. First breakfast was Maine blueberry pancakes and sausage. Lunch was fish chowder, biscuits and spinach salad with chocolate chip bars. Snack was cheese and crackers. Dinner was meat lasagna, green salad, garlic bread with a dessert of the best apple crisp I’ve ever made with whipped cream on the side.

The apple crisp I put together in a fog of nausea as I heaved around in the galley on our 2nd windy day. I was certain it was going to be terrible as I truly threw it together without being able to really understand or plan what I was doing as the whole galley, my own body and everything around me was rolling back and forth on the water. When I tried it later, even I was surprised. Delicious with a perfect combination of tartness, crunch and sweetness with the unsweetened whipped cream I like to make.

There is so much more to say about using an actual ice box, always more about the wood stove, and sailing, but we got back in to harbor at 10 this morning and I worked until 3, then had just enough time to take a shower at the YMCA, do some laundry, track down ear plugs, buy some buttons for my wrists and ginger for my belly before I had to be back to board the next round of passengers. I get the night off tonight, then we’re back out again for a four day trip followed by another weekend trip. I’m ready to go to sleep so I can start again tomorrow dark and early at 3:30, just as the sun is beginning to lighten the sky here in the easternmost state in the nation.

Always, more later . . .

photos of the galley and food are coming next time!